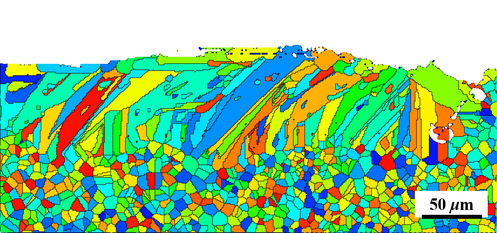

[22] Dina Fouad, Chinnapat Panwisawas, Honghao Ge, Yu-Lung Chiu, Moataz M. Attallah, Achieving the Strength-Ductility Balance Through the Control of the Prior β-Grain Size in Laser Beam Powder Bed Fusion of Ti-6Al-4V[J], Additive Manufacturing, 2025,104842.

[21] Honghao Ge, Shijie Ding, Pengzhi Zhang, et.al, Influence of overlapping process on the distribution of Cr element in laser cladding 316L powder on 45# steel substrate[J], Surface and Coatings Technology, 2024,131249.

[20]傅瑜峰,葛鸿浩,蒋波,等,颗粒对Al-4.5wt.%Cu合金定向凝固汇聚生长得元胞自动机模拟研究[J/OL],有色金属工程,2024.

[19] Honghao Ge, Pengzhi Zhang, Bo Jiang, et. al,Effects of Marangoni Flow on the Composition Distribution of Laser-Cladded 316L on 45 Steel[J],Metallurgical and Materials Transactions A,2024.

[18] Fengli Ren, Tianxin Cao, Yufeng Fu, Honghao Ge*, Xiaofeng Xu, Numerical research on the effects of grain structure on lead concentration distribution in Sn-3 wt.%Pb benchmark experiment using two-phase solidification model coupled with cellular automaton method[J]. International Journal of Heat and Mass Transfer, 2024,125718

[17] 沈盟凯, 董太宁, 葛鸿浩*, 石新升, 等. 316L激光粉末床熔覆IN718偏析带形成过程的模拟[J/OL]. 金属学报, 2024.

[16] 石新升,董太宁,葛鸿浩,邹朋津,等.基于元胞自动机方法与欧拉多相流技术的激光沉积IN718组织形貌模拟[J/OL]. 中国有色金属报, 2024.

[15] 葛鸿浩*, 王永新, 田锡天, 等. 强制流动对Mg-9%Al合金定向凝固组织演化的模拟研究[J/OL], 工程科学学报, 2024.

[14] Fengli Ren, Honghao Ge, et al. Simulation of the dendrite growth during directional solidification under steady magnetic field using three-dimensional cellular automaton method coupled with Eulerian multiphase[J]. International Journal of Heat and Mass Transfer, 2024,218.

[13] Hao Fang, Honghao Ge, et al. Numerical simulation of microstructure evolution during laser directed energy deposition for Inconel 718 using cellular automaton method coupled with Eulerian multiphase[J]. International Journal of Heat and Mass Transfer, 2023,216.

[12] 葛鸿浩*, 王永新, 等. 基于欧拉多相流技术与元胞自动机方法的Mg-9%Al合金凝固组织模拟[J]. 中国有色金属报, 2023.

[11] 张亚周, 葛鸿浩*, 等. 45钢基体激光熔覆316L粉末搭接过程中Cr元素分布机制研究[J]. 中国激光, 2023.

[10] Honghao Ge, Hao Fang, et.al., The evolution of element distribution during laser cladding under static magnetic field [J]. Metallurgical and Materials Transactions A, 2022, 53: 370-376

[9] 张曹伟, 葛鸿浩*, 等. 溶质再分配系数对激光熔覆溶质分布的影响[J]. 中国激光, 2022, 49(2): 129-140. (被评为《中国激光》2022年第2期“优秀论文”)

[8] Honghao Ge, Hanzong Xu, Jiefeng Wang, Jun Li, Jianhua Yao*, Investigation on composition distribution of dissimilar laser cladding process using a three-phase model[J]. International Journal of Heat and Mass Transfer, 2021, 170.

[7] Honghao Ge, Jun Li*, et.al., Numerical simulation of A-Segregation evolution in a 55-ton ingot using four-phase solidification Model[J], Metallurgical and Materials Transactions B, 2021, 52: 2992-3003.

[6] 王杰锋,葛鸿浩*,徐瀚宗,张群莉,姚建华. 感应洛伦兹力对激光熔覆Inconel 718涂层中Fe元素分布的影响[J]. 稀有金属材料与工程, 2021(8): 2799-2806.

[5] 徐瀚宗, 葛鸿浩*, 王杰锋,张群莉,姚建华,VolodymyrS.Kovalenko. 工艺参数对316L不锈钢激光熔覆层中Cr元素分布的影响[J]. 中国激光, 2020, 47(12): 1202004.

[4] Honghao Ge, Fengli Ren, Duanxing Cai, Jun. Li*, Jianguo Li, Gradual-Cooling Solidification Approach to Alleviate Macrosegregation in Large Steel Ingots[J], Journal of Materials Processing Technology, 2018, 262:232-238.

[3] Honghao Ge, Fengli Ren, Jun. Li*, Qiaodan Hu, Mingxu Xia, Jianguo Li, Modelling of ingot size effects on macrosegregation in steel castings[J], Journal of Materials Processing Technology, 2018, 252:362-369.

[2] Honghao Ge, Fengli Ren, Jun Li*, Xiujun Han, Mingxu Xia, Jianguo Li, Four-Phase Dendritic Model for the Prediction of Macrosegregation, Shrinkage Cavity, and Porosity in a 55-Ton Ingot[J]. Metallurgical and Materials Transactions A, 2017, 48 (3): 1139-1150.

[1] Honghao Ge, Jun Li*, Xiujun Han, Mingxu Xia, Jianguo Li, Dendritic model for macrosegregation prediction of large scale castings[J]. Journal of Materials Processing Technology, 2016, 227 308-317.